If you want to buy new energy vehicles in China today, BYD is impossible to ignore. Everyone expects it to continue to improve its product strength, and the focus of attention will naturally fall on the new cars that have been unveiled or will be unveiled soon, such as Destroyer 07, Song L, Qin L, and Chaopai 01. Let’s use a few questions to reveal the technology that will be equipped on BYD’s new car first.

Viewpoint of This Article

- Similar to most car companies, BYD’s new car is also a platform-based product. With product upgrades, most models will transition to the e-platform 3.0.

- For Yangwang products with high level, positioning and high price, the independent Yisifang platform will be used. But the relationship between the two is not completely independent, but an upgrade.

- After years of market training, BYD is more cautious in the development and production of new technologies, and its core is to launch production immediately after debut. Therefore, although new technologies including integrated die-casting have not been exposed, it does not mean that BYD has no reserves.

1. From high configuration to standard configuration?

Today’s new car development is not done alone. The driving texture of products based on the platform research and development concept can be highly unified. Thanks to the large-scale loading and use, the high-end equipment many years ago has become the standard equipment for new cars. Therefore, understanding and understanding the upper and lower limits of the platform can better help us buy a car.

As far as BYD’s future pure electric products are concerned, they will gradually be transformed into research and development based on e-platform 3.0 as they are updated. Since it is 3.0, there must be a previous version. In fact, this is also the development history of BYD in the field of new energy. To some extent, today’s platform 3.0 is developed based on the experience and lessons of its predecessors.

BYD e platform 1.0 can be regarded as the beginning of all stories. Its main goal is to platform the three key components of electric vehicles, such as motor, electronic control and battery. The representative model is BYD e6.

e5 and e6 are representative products of the 1.0 era, and today can be regarded as the place where dreams started. In order to prove its own quality, it has also been pushed to the taxi market, and they can still be seen in some cities today.

The introduction of the model to the market means the success of the technical deduction, and the subsequent launch of the Dynasty series products marks the entry of the BYD e platform into the 2.0 era. As a product we are familiar with, the Dynasty series models were born here, and they also made great contributions to the glory of BYD’s domestic new energy models of 1 million.

It is worth mentioning that this Yuan EV, which was first launched, still has obvious family design details of the previous generation. Looking at it today, it feels somewhat like a world away.

In the e-platform 2.0 era, the research and development goals are three-in-one electric drive, three-in-one charging and distribution, high-safety and high-performance batteries, all-in-one electrical control, and DiLink intelligent network connection. That is, the modularization of the key systems of the vehicle.

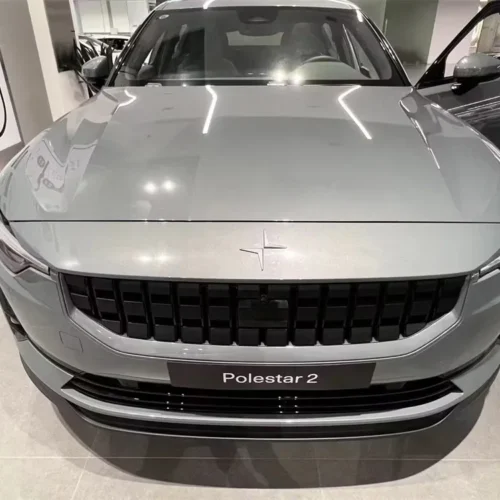

BYD e-platform 3.0 debut model BYD Dolphin, and later released Yuan Plus and Seal. The core of the 3.0 platform is to further strengthen structural integration.

The products in the 3.0 era not only have made great progress in design, but the internal integrated development and design is the focus of the upgrade. This will also become the standard configuration of BYD’s new cars in the future.

An excellent development platform must have a high degree of compatibility and scalability. According to the information released so far, the e-platform 3.0 can develop miniature and small cars with front drive. It can also meet the needs of rear-drive compact and medium-sized cars, and can also hatch mid-size and higher-level products with rear-drive or four-wheel drive.

2. What Does Integration Have to Do with Us?

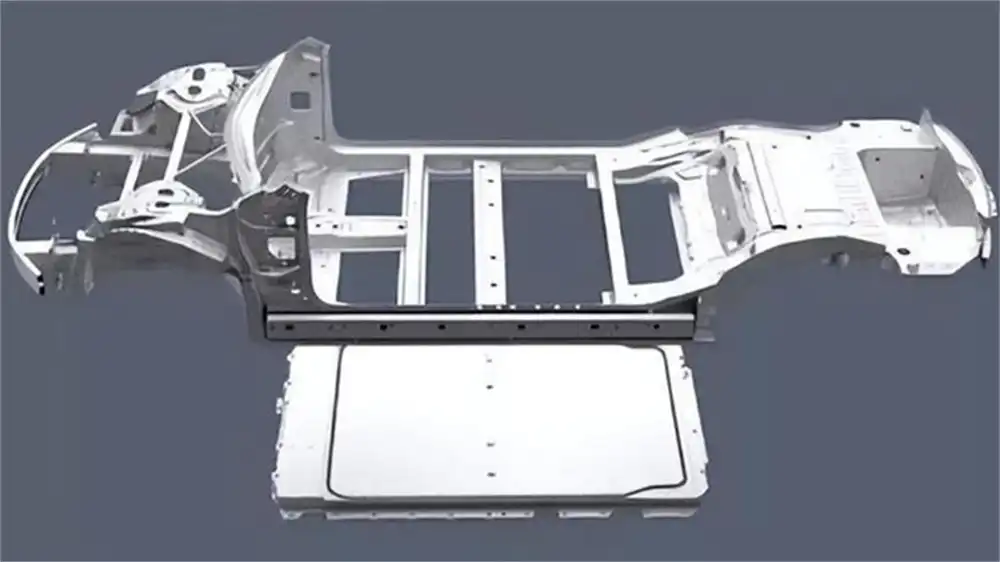

As mentioned earlier, the main feature of the 3.0 era is integration. Among them, the most important thing is the battery and body integration technology, BYD named it CTB, which means Cell To Body. The technical direction is that the body cancels the floor. The purpose is to reduce the structure, increase the battery capacity, and increase the cruising range.

CTB is one of the most popular battery and body development technologies at present, and it is also the key direction of BYD’s research and development. It is not just the reduction of the battery cover or the reduction of the underbody. After all, the height of this part is cut, and the user can hardly feel it.

The in-depth battery structure adjustment and the optimized passive safety design of the body are the important reasons why it can be called the future development direction.

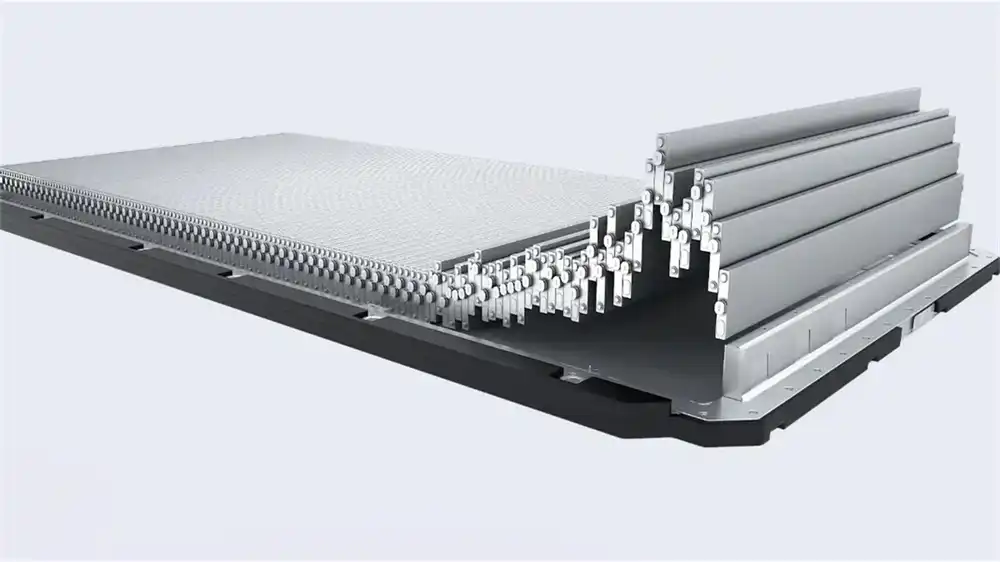

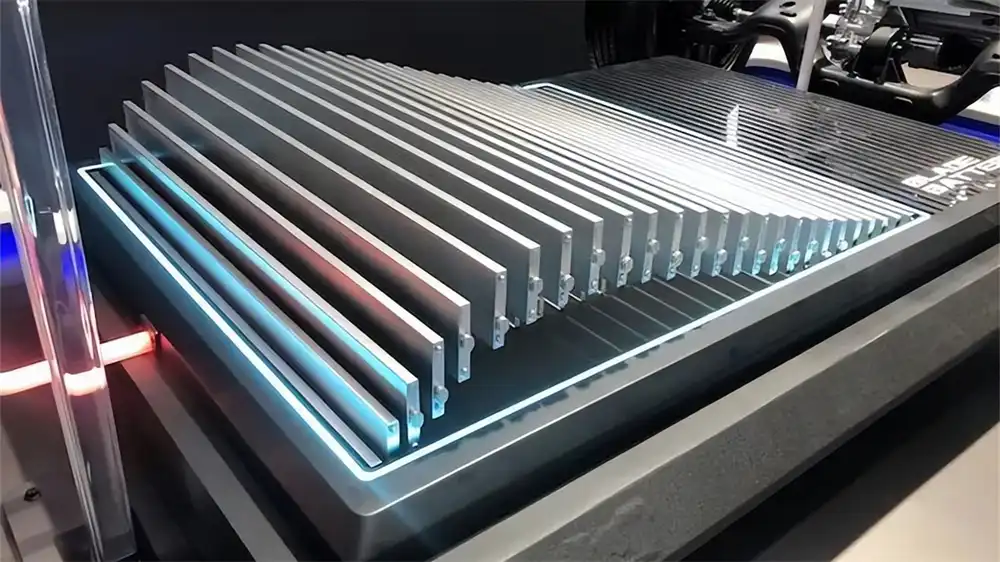

Another cornerstone of the mass production of CTB technology lies in the battery pack and the underlying cell technology, that is, the blade battery. The module is inserted vertically into the battery pack, reducing the original support structure, thereby directly increasing the energy density. Compared with the old technology, the volume utilization rate is increased by 77%, and the energy density is increased by 10%.

In the initial “oil to electricity” era, the passive safety structure followed the development idea of fuel vehicles. The side members that connect to the crash beam pass through the body, as well as the battery pack. In order to enhance frontal crash safety, the front part of the floor has a reinforcement structure.

In addition, the battery pack technology is also a bit raw, and the space in the middle of the floor cannot be fully utilized. The pure electric cruising range is not even as good as today’s plug-in hybrid models.

In the initial era of the “pure electric platform” that followed, the passive safety structure of the body was optimized. More front and rear protective structures have also been added inside the battery pack.

Compared with the previous era, the battery pack is significantly larger, but limited by the body structure, it still cannot fully utilize the space in the middle of the floor.

Entering the era of pure electric platform development, the passive safety structure is significantly different from that of fuel vehicles. Compared with the previous pure electric platform, the underbody of the vehicle body becomes flat, so that a larger battery pack can be arranged. However, in order to ensure the structural strength of the body, part of the longitudinal beam was moved to the battery pack.

In the future CTB era, the bottom plate will also be flat to facilitate the arrangement of battery packs. The battery and the body together form a force transmission structure to ensure passive safety, and more battery modules can be arranged in the saved longitudinal beam space.

Using CTB technology, there is no need for longitudinal beams inside the battery pack, and it becomes a force-transmitting component together with the body. The strength of the surrounding structure of the vehicle body can be further enhanced. According to the official statement, the force transmission ratio of the forward collision battery pack can reach 20%, and the ratio of side collision force transmission can reach 30%. This further improves passive safety performance.

The complexity of post-maintenance and the resulting increase in use costs are unavoidable problems with related technologies, and this is also a shortcoming that the Pingshan development team strives to solve.

Integrated technologies will face the challenge of maintenance economics, and there are already countless past cases in the field of consumer electronics for reference. In order to reduce user costs, BYD’s engineering team has optimized the connection structure between the battery pack and the body, reducing parts and thus reducing maintenance costs. As for the problem of battery damage, there is no need to worry, after all, the official provides a lifetime warranty service.

3. What Else Is There to Tell?

Since the development of automobiles, it is no longer a trick that was eaten all over the world. The dividends brought by a single advanced technology are far from meeting the various needs of consumers. In addition to the integrated design concept, e-platform 3.0 has optimized the details. In the end, it is more important to achieve an improvement in the overall user experience than how much you are ahead of your opponent.

In the information released earlier, the official specifically emphasized that the motor integration has evolved from the original three-in-one to eight-in-one. Friends who are familiar with consumer electronics may have already felt the benefits of integration. A more compact structure is undoubtedly smaller in size and more convenient to carry and use, thus expanding more usage scenarios.

BYD’s eight-in-one is not a gimmick, but a consideration of the layout of the power system. In the product series, in order to increase the seating space, the rear motor needs to be arranged in the trunk instead of under the seat. The space here is smaller than that of the front cabin, and the traditional three-in-one design undoubtedly needs to occupy more.

On the other hand, integration also considers the thermal management level of the system. The high performance and integration look good, but there is also the problem of overheating at high loads, and the resulting power reduction is something no one wants to see.

Those who are familiar with BYD also know that they have been developing and manufacturing IBGT by themselves. In addition to the degree of technical freedom, this also involves cost. According to relevant statistics in 2018, in a pure electric vehicle, IGBT accounts for about half of the cost of the drive motor system. The driving motor system accounts for 15-20% of the vehicle cost, which means that the IGBT accounts for 7-10% of the vehicle cost.

Balancing cost and efficiency is the eternal melody of car companies, and I believe that everyone does not want to pay for things that are not used. Therefore, in the current plan, silicon carbide components are more inclined to performance models and high-end positioning products, such as Seal and Yangwang brand models. Relatively civilian and high-volume products continue to use ordinary IGBTs.

As mentioned earlier, high temperature is naturally indispensable, and low temperature is also indispensable, which is also a pain point in the use of new energy vehicles. On the one hand, everyone hopes that the cabin in winter can be as comfortable as possible, and on the other hand, they don’t want to see the cruising range halved. Heat pump air conditioners are the solution to meet the seemingly contradictory needs at both ends of the balance these years.

In extreme cases, traditional PTC assistance is still required when there is less heat in the natural temperature. The solution given by BYD is to use 1kW low-voltage PTC heating, which can save energy as much as possible. Of course, user experience is also a development goal that cannot be compromised. This is the time for the core of the heat exchange system to debut.

Of course, the 1kW low-pressure PTC heating cannot meet the auxiliary heating demand under extreme working conditions. BYD’s solution is similar to Tesla’s, which is to properly “export” the working heat of the electric drive system through the integrated valve. On the one hand, it is supplied to the battery pack for heat preservation, and on the other hand, it is sent to the passenger compartment to meet the comfort requirements. Of course, this puts forward extremely high requirements on logic design and switching speed.

Final Words:

The former BYD was looked down upon by others, but now BYD is incomprehensible to many people. I believe that in the future it will become a goal that many people cannot catch up with. This private car company has been questioned, and today’s market sales are positive feedback from their hard work in the past. Remaining in awe of technology, working hard on positive research and development, and thinking about how to implement it shows the attitude of a mature car company. There may still be deficiencies in it, but there is no doubt that these problems and shortcomings will be made up for with today’s attitude. I sincerely hope that in the next ten years, BYD from China will stand at the top of the world auto market.